High-Efficiency

Cold Storage Warehousing

with Custom Dimensions and

Climate Monitoring

Our cold storage and food processing rooms are fully customisable, insulated environments designed for operations of any size. They feature food-grade insulated metal panels and precision sealing systems that outperform conventional warehouse builds in thermal efficiency and long-term durability.

Every structure is built from industrial-grade materials and designed in alignment with GMP principles, ensuring long-term reliability and adaptability as your operational needs evolve.

Cold Storage Warehousing: Designed for Temperature-Sensitive Operations

Turnkey build, high-performance insulation, remote monitoring, and ongoing support to protect your inventory and reduce energy costs.

Superior Thermal Performance

Insulated panels maintain consistent low temperatures, reducing energy consumption and protecting sensitive goods from spoilage.

Modular and Scalable Design

Built to fit your footprint and layout, each unit can be expanded to match evolving operational needs.

Built to GMP standards

Every build follows strict quality protocols using industrial-grade materials, durability, and long-term reliability across agriculture, pharma, and logistics sectors.

Remote Monitoring and Control

VertiOne integration allows real-time tracking of temperature, humidity, and system status from anywhere.

Food Safe Rooms (13°C – 28°C)

- Built with IMP and SIP panels for insulation and structural integrity

- Hygienic surfaces suitable for food handling

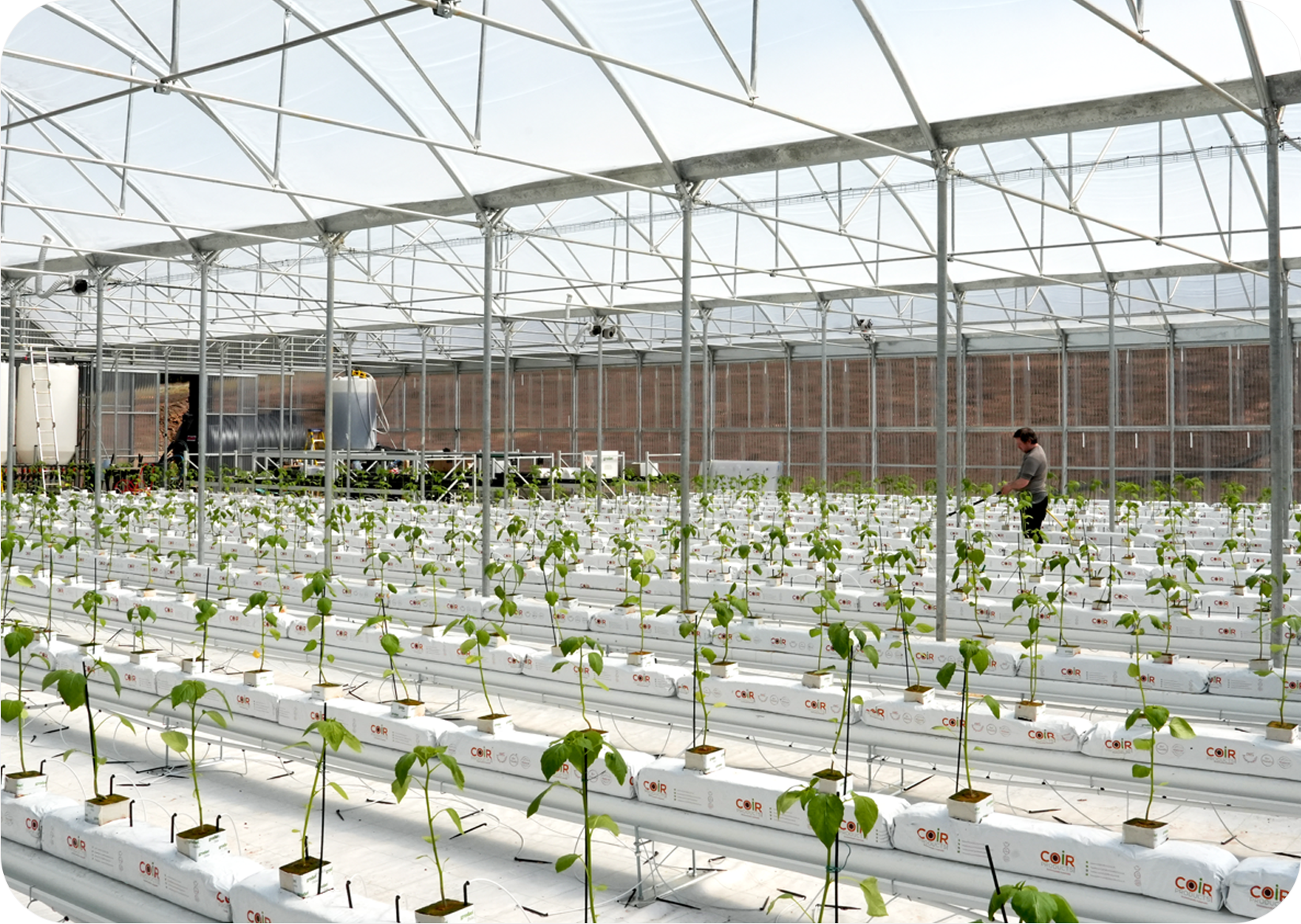

- Flexible layout for storage or vertical farming setups

- Ideal for warehouses, vertical farms and commercial storage

- Easy to maintain and clean

- Provides a reliable base for future upgrades

Chiller Rooms (2°C – 5°C)

- Chiller units for precise temperature control

- Food-grade IMP panels for insulation and structure

- Ideal for commercial kitchens, food processing and storage

- Perfect for perishable goods and sensitive ingredients

- Keeps products fresh and safe while reducing energy costs

- Can be scaled or adapted to specific industrial or commercial needs

Freezer Rooms (-18°C – -21°C)

- Freezer units with reinforced insulation for sub-zero performance

- Food-grade panels and materials suitable for extreme cold

- Built for industrial, commercial and agricultural storage

- Perfect for frozen foods, long-term storage and industrial processing

- Maintains product quality and safety over extended periods

- Energy-efficient design with robust structural integrity